-

Throughout my life, I've completed quite a large number of projects, ranging from creating a simple styrofoam cutter, all of the way to helping build a solar-powered car. I describe some of these projects below. Feel free to click on any of the images to open a zoomed-in version in another tab. It's worth noting that I've not updated this projects page for about four years - I've done a lot since 2020. Updates may come soon (or they may not).

-

Solar Vehicle Project

During the fall semester of 2019, I traveled to Australia with 17 other team members and competed in the Bridgestone 2019 World Solar Challenge (In the linked article, I can be seen in the fourth picture down, propping open the front array of our car at a control stop after driving, to protect our car's batteries from the extreme heat). While there, one of my main duties was rewiring the car's vital systems, as it had been done hastily in the past and was giving us significant issues while driving. I was also one of the car's drivers, and drove across the Australian outback in the race. Our team placed 5th of 12 in our class, the cruiser class.

-

Computer

I needed a computer that would be able to CAD, design, and simulate at a very high level. So, I custom-designed and built a computer boasting an Intel Xeon E5-2698 v3 Processor, an NVIDIA GeForce RTX 2070 Super Graphics Card, 128GB of DDR4 2133mHz RAM, and approximately 14TB of combined SSD and archival-grade HDD storage. It also features a number of peripherals, some of which are SATA and m.2 expansion cards, a dual-SAS RAID card, and a quad SATA hot-swap bay.

-

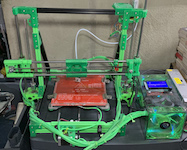

3D Printer

The 3D Printer was a spin-off of the OB1.4, an open-source 3D printer. I custom-designed many of the parts using CAD software, and then 3D printed them for use on my own printer. This project was done during my sophomore and junior years of high school. The last image links to a video.

-

Mini Board

Consisting of six different prototypes and the final product, the mini board was a custom designed longboard with the goal of being small enough and light enough to fit inside of my backpack. The final board consists of a carbon fiber laminated aluminum honeycomb sandwich panel deck weighing in at 3 oz, and custom-machined nuts, bolts, and washers made of aluminum for minimal weight. The last image links to a video of me riding the sixth prototype.

-

Aluminum Forge

The aluminum forge was an idea originally sparked from a youtube video, in which a youtuber constructed a backyard aluminum forge capable of melting and casting aluminum. So, I constructed the same, but took mine a bit further. As opposed to a traditional bellows (or in the video, a small hair dryer), I utilized a very powerful vacuum motor. This allowed the forge to reach incredibly high temperatures. In fact, the forge was tested to melt much more than just aluminum, and could also liquify brass, copper, and even cast iron.

-

Styrofoam Cutter

The styrofoam cutter was built as a sort of add-on to the aluminum forge. The simplest method of casting with a forge is to perform lost-foam casting (make a styrofoam positive of the object and pour the aluminum on that). So, I constructed a simple styrofoam cutter out of a picture hanging wire, some PVC piping, and a fluorescent light ballast transformer. The wire heats up and allows one to cut and shape styrofoam to any shape necessary. The last image links to a demonstration video.